-

ジェイク・ミラー組み立てラインの重要なVFD交換のため、inverters-vfd.comに賭けてみました。製品は完璧に適合しただけでなく、以前のサプライヤーよりも手頃な価格でした。その安定性により、頻繁に発生していたトリップの問題が解消されました。優れた価値と、産業用コンポーネントの信頼できるパートナーです。

ジェイク・ミラー組み立てラインの重要なVFD交換のため、inverters-vfd.comに賭けてみました。製品は完璧に適合しただけでなく、以前のサプライヤーよりも手頃な価格でした。その安定性により、頻繁に発生していたトリップの問題が解消されました。優れた価値と、産業用コンポーネントの信頼できるパートナーです。 -

サラ・チェンinverters-vfd.comの技術チームは非常に役立ちました。サーボモーターの用途を説明したところ、彼らは優れた動的応答を持つモデルを推奨してくれました。設置はスムーズで、精度がサイクルタイムを改善しました。専門的な指導と高性能な製品に感謝します!

サラ・チェンinverters-vfd.comの技術チームは非常に役立ちました。サーボモーターの用途を説明したところ、彼らは優れた動的応答を持つモデルを推奨してくれました。設置はスムーズで、精度がサイクルタイムを改善しました。専門的な指導と高性能な製品に感謝します! -

デイビッド "ビッグ D" コワルスキー複数のPLCユニットとHMIの注文は正確に履行され、驚くべき速さで発送されました。それらを統合して以来、当社の制御システムの通信はより堅牢になりました。ロジスティクスとこれらのコンポーネントの確かな性能に感銘を受けています。全体的に手間のかからない経験でした。

デイビッド "ビッグ D" コワルスキー複数のPLCユニットとHMIの注文は正確に履行され、驚くべき速さで発送されました。それらを統合して以来、当社の制御システムの通信はより堅牢になりました。ロジスティクスとこれらのコンポーネントの確かな性能に感銘を受けています。全体的に手間のかからない経験でした。 -

エミリー・ホワイトデリケートな試験環境向けに、低騒音のスピンドルモーターが必要でした。購入したユニットは、ささやくように静かに動作し、安定したトルクを維持しています。品質は、これまで使用してきた大手ブランドを凌駕し、価格はわずかです。特殊用途に最適です。

エミリー・ホワイトデリケートな試験環境向けに、低騒音のスピンドルモーターが必要でした。購入したユニットは、ささやくように静かに動作し、安定したトルクを維持しています。品質は、これまで使用してきた大手ブランドを凌駕し、価格はわずかです。特殊用途に最適です。

Environmentally Adaptive HD2000 Systems: Operates from -25°C to +65°C and Humidity Up to 85%

試供品およびクーポンのための私に連絡しなさい。

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

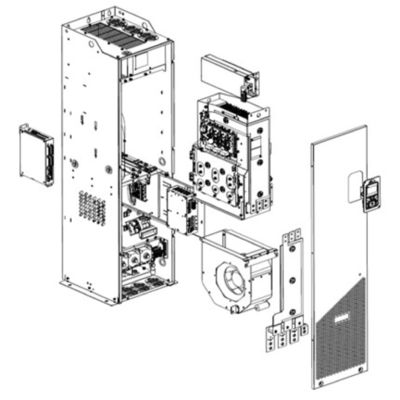

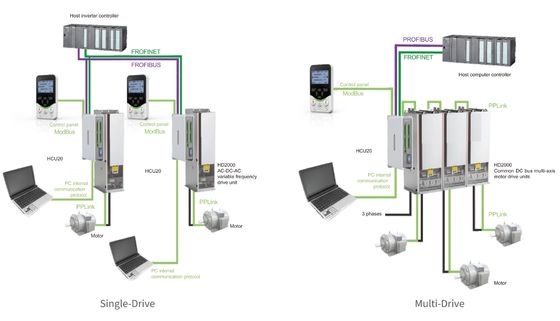

x| シングル/マルチドライブ | 柔軟なシステムで2~4つの四角を支えるユニット/キャビネット | モジュラー設計 | アプリケーションの柔軟性と包括的なシステム統合を可能にします |

|---|---|---|---|

| 矯正装置 | 汎用的な電源変換のための基本/スマート/PWM直流装置 | マックス 単位の電源 | 1400kW (空気冷却),2800kW (液体冷却) |

| 電圧レベル | 400V,690V,1140V,1380V | マックス パラレル動作力 | 11200kW (空気冷却), 22400kW (液体冷却) |

| ハイライト | VFD drive with wide temperature range,Variable frequency drive for high humidity,HD2000 VFD with extreme environment adaptability |

||

| Model | HD2000 Series Low Voltage Engineering Inverter(Liquid-cooled) | |

|---|---|---|

| Basic Rectifier | Input voltage | 4:380V~480V,6:500V~690V |

| Input frequency | (50Hz/60Hz)±6% | |

| Output voltage | Input voltage * 1.32 (Under full-load condition) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥99% Efficiency | |

| Protection eunctions | Protection functions: Overheating protection, soft-start protection, Interlock | |

| protection, and more. | ||

| Intelligent rectifier | Input voltage | 4:380V ~ 480V,6: 500V ~ 690V |

| Input frequency | 47 ~ 63Hz | |

| Output voltage | Input voltage * 1.3 (Under full-load condition) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥98.5% Efficiency | |

| Protection functions | Protection functions: Overheating protection, Overcurrent protection, IGBT pass-through protection, and more | |

| PWM rectifier | Input voltage | 4:380V~480V,6:500V~690V,9:1140V,A:1380V |

| Input frequency | 47 ~ 63Hz | |

| Output voltage | Input voltage * 1.5 (Under rated conditions) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥98% Efficiency (Including LCL filter unit) | |

| Power factor | Adjustable (Factory setting at 1) | |

| Protection functions | Protection functions: Overheating protection, Overcurrent protection, Overload protection, IGBT pass-through protection, and more. | |

| Inversion | Rated Input voltage | 4:410Vdc~780Vdc,6:550Vdc~1100Vdc,9:1488Vdc~2200Vdc, |

| A:1488Vdc~2200Vdc | ||

| Output voltage | 0 ~ Rectifier AC input voltage | |

| Output frequency | 0 ~ 500Hz | |

| Speed range | V/F:1:50 OLVC:1:200 CLVC:1:1000 | |

| Speed stability | OLVC:0.2% CLVC:0.01% | |

| Speed fluctuation | OLVC:0.2% CLVC:0.1% | |

| Starting torque | OLVC:150%(0.5Hz) CLVC:200%(0Hz) | |

| Torque control | V/F: Unsupported OLVC:Supported CLVC: supported | |

| Torque accuracy | OLVC:5% CLVC:5% | |

| Torque response time | OLVC:5ms CLVC:5ms | |

| Speed response time | OLVC:100ms CLVC:100ms | |

| Dynamic speed drop equivalent | OLVC:0.5%*s CLVC:0.3%*s | |

| Environmental conditions | Temperature | -15℃ ~ +40℃ Without derating, +40℃ ~ +55℃ derating applies |

| Humidity | 5% ~ 95% Mon-condensing | |

| Altitude | ≤4000m, Derating applies from 2000m to 4000m | |

| Mechanical data | Anti-vibration performance | Complies with IEC 60721-3-3:2002 |

| Protection level | IP00 / IP20 / IP40 | |

| Safety level | Complies with UL 508C-2004 | |

| Cooling method | Liquid-cooled | |

![]()

![]()

Focus: Industrial Reliability, Energy Efficiency, and Compliance

-

Q: Does the HD2000 VFD meet UL safety standards for industrial use in the U.S.?

A: Yes, the HD2000 series complies with UL 508C-2004, ensuring top-tier safety and reliability for demanding American industrial environments. -

Q: How does the HD2000 help reduce operational costs in manufacturing?

A: With operating efficiency up to ≥99% in basic rectifier models, the HD2000 minimizes energy waste, leading to significant cost savings over time. -

Q: Can the drive handle sudden load spikes common in U.S. factories?

A: Absolutely. It supports 150% overload for 60 seconds and DC overload for 5 seconds, providing robust performance during peak demands. -

Q: What cooling options are available for high-temperature regions like Texas?

A: Both air-cooled and water-cooled models are offered, with operating temperatures up to +55°C (with derating), ideal for varied climates. -

Q: Is the HD2000 suitable for multi-drive systems in large plants?

A: Yes, its modular design supports complex single-drive or multi-drive setups, making it perfect for scalable American industrial applications. -

Q: How does the product ensure long-term durability?

A: With protection functions like overheating, overcurrent, and soft-start, plus anti-vibration compliance (IEC 60721-3-3), it offers exceptional longevity.

Focus: Precision Engineering, Environmental Standards, and High Performance

-

Q: How precise is the speed control in the HD2000 for German engineering applications?

A: With CLVC mode, speed stability is 0.01% and speed fluctuation is 0.1%, meeting the high precision required in German automation and machinery. -

Q: Does the HD2000 support torque control for sensitive processes?

A: Yes, OLVC and CLVC modes enable torque control with 5% accuracy and 5ms response time, ideal for precision-driven industries. -

Q: Is the product compliant with European environmental and safety norms?

A: While explicitly tested to international standards, it aligns with IEC anti-vibration norms and offers IP00-IP40 protection levels for safe operation. -

Q: How efficient is the PWM rectifier under full load?

A: The PWM rectifier achieves ≥98% efficiency (including LCL filter), ensuring energy savings and compliance with German efficiency directives. -

Q: Can the HD2000 operate in variable frequency ranges for specialized equipment?

A: Yes, output frequency ranges from 0 to 500Hz, supporting diverse motor types used in German manufacturing. -

Q: What makes the HD2000 ideal for harsh industrial environments?

A: With wide humidity tolerance (5%-95% non-condensing) and robust protection functions, it performs reliably in challenging conditions.

Focus: Compact Design, High Frequency, and Technology Integration

-

Q: Is the HD2000 available in compact sizes for space-limited Japanese facilities?

A: Yes, compact air-cooled models (5.5–160kW) and modular units allow flexible installation in tight spaces. -

Q: How does the drive support high-speed applications common in Japan?

A: With an output frequency range of 0–500Hz and CLVC starting torque of 200% at 0Hz, it excels in high-speed automation and robotics. -

Q: What protection features prevent damage in frequent start-stop cycles?

A: Soft-start protection, IGBT pass-through protection, and overload capabilities ensure smooth operation and extended equipment life. -

Q: Can the HD2000 integrate with smart factory systems?

A: Yes, the intelligent rectifier and PWM options support advanced control and monitoring, aligning with Japan’s Industry 4.0 initiatives. -

Q: How does the product perform in high-humidity coastal areas?

A: With 5%–95% non-condensing humidity tolerance, it remains reliable in humid climates like Osaka or Tokyo. -

Q: What efficiency levels can we expect for energy-conscious Japanese markets?

A: Efficiencies range from ≥98% to ≥99%, reducing operational costs and supporting sustainability goals.