-

ジェイク・ミラー組み立てラインの重要なVFD交換のため、inverters-vfd.comに賭けてみました。製品は完璧に適合しただけでなく、以前のサプライヤーよりも手頃な価格でした。その安定性により、頻繁に発生していたトリップの問題が解消されました。優れた価値と、産業用コンポーネントの信頼できるパートナーです。

ジェイク・ミラー組み立てラインの重要なVFD交換のため、inverters-vfd.comに賭けてみました。製品は完璧に適合しただけでなく、以前のサプライヤーよりも手頃な価格でした。その安定性により、頻繁に発生していたトリップの問題が解消されました。優れた価値と、産業用コンポーネントの信頼できるパートナーです。 -

サラ・チェンinverters-vfd.comの技術チームは非常に役立ちました。サーボモーターの用途を説明したところ、彼らは優れた動的応答を持つモデルを推奨してくれました。設置はスムーズで、精度がサイクルタイムを改善しました。専門的な指導と高性能な製品に感謝します!

サラ・チェンinverters-vfd.comの技術チームは非常に役立ちました。サーボモーターの用途を説明したところ、彼らは優れた動的応答を持つモデルを推奨してくれました。設置はスムーズで、精度がサイクルタイムを改善しました。専門的な指導と高性能な製品に感謝します! -

デイビッド "ビッグ D" コワルスキー複数のPLCユニットとHMIの注文は正確に履行され、驚くべき速さで発送されました。それらを統合して以来、当社の制御システムの通信はより堅牢になりました。ロジスティクスとこれらのコンポーネントの確かな性能に感銘を受けています。全体的に手間のかからない経験でした。

デイビッド "ビッグ D" コワルスキー複数のPLCユニットとHMIの注文は正確に履行され、驚くべき速さで発送されました。それらを統合して以来、当社の制御システムの通信はより堅牢になりました。ロジスティクスとこれらのコンポーネントの確かな性能に感銘を受けています。全体的に手間のかからない経験でした。 -

エミリー・ホワイトデリケートな試験環境向けに、低騒音のスピンドルモーターが必要でした。購入したユニットは、ささやくように静かに動作し、安定したトルクを維持しています。品質は、これまで使用してきた大手ブランドを凌駕し、価格はわずかです。特殊用途に最適です。

エミリー・ホワイトデリケートな試験環境向けに、低騒音のスピンドルモーターが必要でした。購入したユニットは、ささやくように静かに動作し、安定したトルクを維持しています。品質は、これまで使用してきた大手ブランドを凌駕し、価格はわずかです。特殊用途に最適です。

Self Developed IGBT Platform Evaluates Module Design Performance

| 起源の場所 | 中国 |

|---|---|

| ブランド名 | COENG |

| 証明 | CE |

| モデル番号 | HV300-12 |

| ドキュメント | HV300.docx |

| 最小注文数量 | 1 |

| パッケージの詳細 | 木製の箱 |

| 受渡し時間 | 10-30Working Days |

| 支払条件 | L/C、T/T、Western Union |

| 供給の能力 | 20000SETS/YEAR |

試供品およびクーポンのための私に連絡しなさい。

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 電力範囲 | 0.4kW~500kW | 入力電圧 Uin | 200V (-15%) ~ 240V (+10%) 1PH/3PH 380V (-15%) ~ 480V (+10%) 3PH 500V 500V (-15%) ~ 690V (+10%) 3PH |

|---|---|---|---|

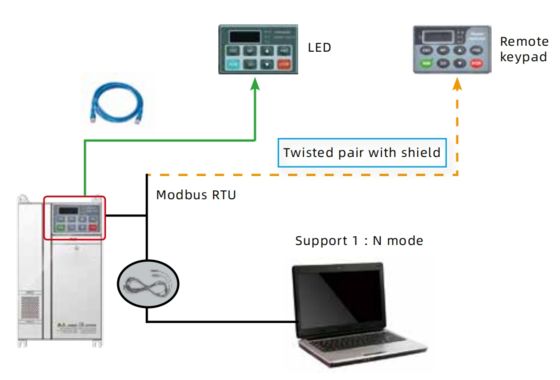

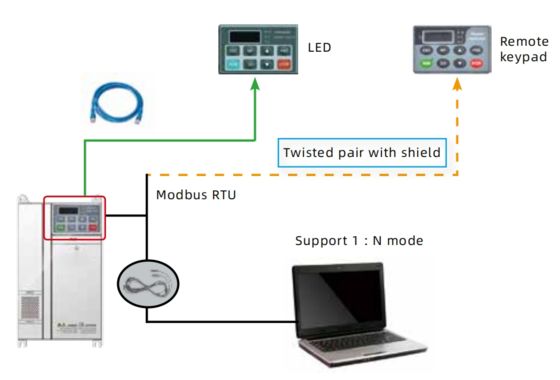

| 入力頻度 | 50Hz/60Hz±5% | 通信インターフェイス | RS485,RJ45 |

| 通信プロトコル | MODBUS RTU | 湿度 | <90% RH 凝縮しない |

| 操作の温度 | -20°C~+40°C (40°C~55°Cでの降温で動作する) | ||

| ハイライト | IGBT module performance evaluator,Vector frequency inverter design tool,IGBT platform with warranty |

||

Vector Frequency Inverter Product Description

The HV300 Series inverter is a cutting-edge, multi-function universal vector frequency inverter, also known as a variable frequency drive (VFD) or AC drive. This recently developed inverter incorporates advanced open-loop and closed-loop vector control technology, allowing precise control of asynchronous motors.

Designed with a focus on software functionality, performance enhancement, and reliability, the HV300 inverter offers a more compact size without compromising expandability. It provides users with a wider range of communication capabilities, enabling seamless integration into various industrial systems.

With its user-friendly interface and intuitive controls, the HV300 inverter ensures simpler operation and configuration. Its comprehensive features and parameters can be easily accessed and adjusted to meet specific application requirements.

The HV300 Series inverter offers advanced functionality, enhanced performance, and increased reliability. It is a versatile solution for various industrial applications, providing precise control, efficient operation, and simplified integration into existing systems.

Variable Frequency Inverter VFD Product Technical Specification

| Specification | Value |

|---|---|

| Input Voltage | 200V (-15%) ~ 240V (+10%) 1PH/3PH; 380V (-15%) ~ 480V (+10%) 3PH 500V;500V (-15%) ~ 690V (+10%) 3PH |

| Input Frequency | 50Hz/60Hz±5% |

| Maximum Supply Imbalance | ≤3% |

| Output Voltage | 0V ~ Uin |

| Output Frequency | 0Hz ~ 300Hz |

| Power Range | 0.4kW ~ 500kW |

| Mounting Method | Cabinet installation, Through panel, surface mounting |

| Ingress Protection | IP20, IP21 (by adding optional device) |

| Torque Accuracy | ≤5% (OLVC) |

| Storage Temperature | -40 ℃~+70℃ |

| Starting Torque | 0.5Hz: 150% (OLVC), 1Hz: 150% (OLVC) |

Variable Frequency Inverter VFD Product Typical Application

Oilfield Pumping Unit:

- Location: Oilfield

- Power: 22kW

- Efficiency: Achieve significant power savings of over 30% while protecting the grid and equipment from overcurrent issues.

- Key Advantages: Versatile voltage range for seamless adaptation to demanding grid conditions; Smooth speed control with low starting current, ensuring minimal impact on the grid; Equipped with built-in EMC filter and standard-configured DC reactor, reducing radiation.

![]()

Steel Plant Roller:

- Location: Tianjin steel plant

- Power: 22kW, 30kW, 37kW, 45kW

- Performance: Ensures exceptional operational stability with a fault rate below 1%.

- Key Advantages: Designed to handle reciprocating acceleration and deceleration, providing reliable performance; Capable of supporting long-term continuous operation; Built to withstand high temperatures and meet stringent protection requirements in steel workshops; Facilitates integration into Profibus DP network.

![]()

Steel Plant Cold Saw:

- Location: Tangshan steel plant

- Power: 450kW

- Performance: Enables high overload operation, maintaining stable speed control to meet process demands.

- Key Advantages: Exceptional overload capacity for heavy-duty operations; Quick response and precise speed control, even at high speeds; Engineered to withstand high temperatures and fulfill rigorous protection requirements in steel workshops; Supports seamless integration into Profibus DP network.

![]()

1. FAQ for South Korea

-

Q: Is the VFD suitable for high-tech manufacturing?

A: Yes, with precise control and communication capabilities. -

Q: How does it support Korea’s green energy policies?

A: High efficiency and low harmonics align with national standards. -

Q: Can it integrate with Korean PLC systems?

A: Yes, Profibus and other protocols are supported. -

Q: How does it handle seasonal temperature variations?

A: Operating range from -40°C to +70°C ensures year-round reliability. -

Q: Is it used in shipbuilding or marine applications?

A: Yes, with optional corrosion protection. -

Q: What is the harmonic performance?

A: Meets IEEE 519 standards with DC reactor. -

Q: Can I customize the control logic for automation?

A: Yes, the built-in PLC allows full customization. -

Q: How reliable is the short-circuit protection?

A: It uses advanced IGBT technology for instant response. -

Q: Are Korean language interfaces available?

A: Yes, key parameters and alarms can be displayed in Korean. -

Q: What is the lead time for Busan?

A: We deliver within 3–5 days.

2. FAQ for Australia

-

Q: Is the VFD suitable for mining applications?

A: Yes, robust design and heat protection make it ideal. -

Q: How does it handle Australia’s 230V/400V grid?

A: Fully compatible with input voltage ranges. -

Q: Can it operate in remote areas with limited cooling?

A: Yes, efficient thermal design requires minimal cooling. -

Q: Does it support solar pumping systems?

A: Absolutely—compatible with variable DC inputs. -

Q: How does it reduce motor wear?

A: Soft start and adjustable acceleration curves extend motor life. -

Q: Is it compliant with Australian standards?

A: Yes, meets AS/NZS 3000 and other relevant standards. -

Q: Can it be used in livestock farming?

A: Yes, with protection against dust and moisture. -

Q: What communication options are available?

A: Profibus standard; Ethernet/IP optional. -

Q: How easy is troubleshooting?

A: Built-in diagnostics and clear fault messages simplify repairs. -

Q: Is local technical support available?

A: Yes, we have partners in all major states.

3. FAQ for Canada

-

Q: How does the VFD perform in cold climates?

A: Operating down to -40°C, it is perfect for Canadian winters. -

Q: Is it suitable for forestry equipment?

A: Yes, high torque and rugged design meet demanding conditions. -

Q: Can it help reduce energy costs in heating systems?

A: Yes, by optimizing motor speed in pumps and fans. -

Q: Does it support French and English interfaces?

A: Yes, multilingual support is available. -

Q: How does it handle voltage spikes from hydroelectric sources?

A: Built-in surge protection and wide voltage tolerance ensure safety. -

Q: Is it certified by Canadian standards?

A: Yes, CSA and UL certifications are available. -

Q: Can it be used in food and beverage processing?

A: Yes, with optional stainless steel enclosures. -

Q: What is the typical payback period?

A: Often less than 12 months due to energy savings. -

Q: How reliable is the IGBT under frequent load changes?

A: Excellent—adaptive control maintains stability. -

Q: Is remote monitoring supported?

A: Yes, via Profibus or optional wireless modules.

4. FAQ for Brazil

-

Q: How does the VFD handle Brazil’s 220V/380V system?

A: Fully compatible with both voltage ranges. -

Q: Is it suitable for sugarcane processing or agriculture?

A: Yes, with high starting torque and environmental resilience. -

Q: Can it reduce energy costs in high-tariff regions?

A: Absolutely—improved efficiency cuts electricity bills. -

Q: How does it perform in humid, tropical climates?

A: PCB coating and thermal management prevent moisture damage. -

Q: Is local technical support available in Portuguese?

A: Sim, oferecemos suporte em português. -

Q: Can it be used with Brazilian motor brands?

A: Yes, fully compatible. -

Q: What is the harmonic distortion level?

A: Below 5%, meeting Brazilian grid codes. -

Q: How easy is installation for small farms?

A: Very easy—plug-and-play setup with minimal wiring. -

Q: Does it support generator operation?

A: Yes, stable performance with generator sets. -

Q: What is the warranty coverage?

A: 2 years, with extended options.